Industry 4.0 Solutions

I 4.0 & F 4.0

Completing our comprehensive and effective business assessment is essential! Identify your business strengths, uncover opportunities, and drive strategic growth. Start now!

Start Your Journey Towards CHANGE

Our readiness assessment tools, Industry and Foundry 4.0, are tailored to help you understand your unique strengths and areas for improvement. With detailed analytics and customized feedback, you'll receive a clear roadmap for personal and professional development. Whether you're aiming to elevate your skills, improve team performance, or make strategic decisions, this tool is designed to meet your needs.

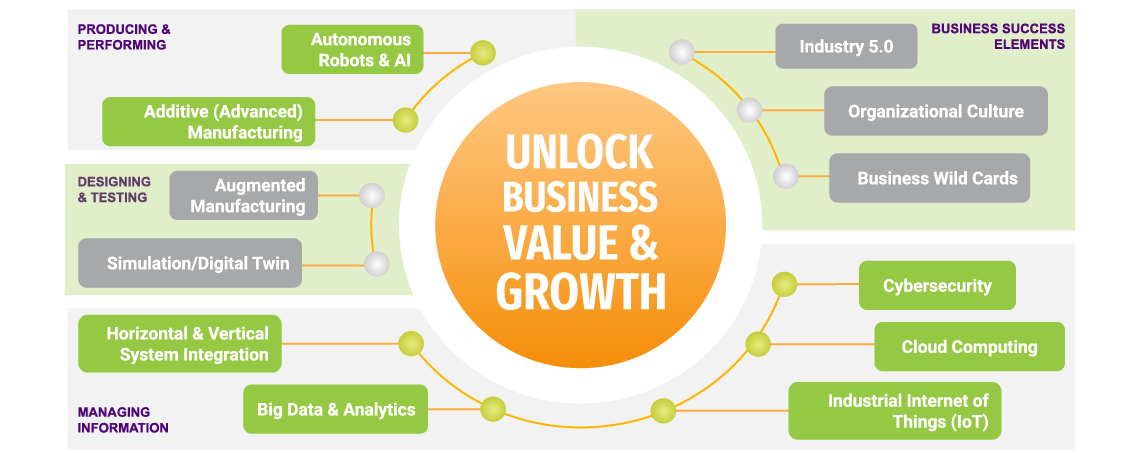

INDUSTRY & FOUNDRY 4.0 Readiness Technology Pillars

Empower Your Growth Potential

A great strategy to begin your transformation is to register for and start using our free, comprehensive, personalized Foundry 4.0 readiness assessment tool. This tool will help you evaluate your current capabilities and identify areas for improvement, setting you on the path to achieving Industry 4.0 excellence.

"Embracing Industry 4.0 is crucial for businesses in the Midwest

and the entire US to stay competitive in the global market.

By integrating advanced technologies such as IoT, AI,

and automation, companies can enhance productivity,

drive innovation, and create resilient supply chains,

ensuring sustainable growth and economic prosperity."

Randy Pilkington

Retired Director, UNI Business and Community Services (BCS)

Iowa’s Hidden Hotbed of Innovation

Why This Story Matters...

INNOVATION IOWA recently published a compelling article spotlighting the quiet but powerful transformation unfolding across our state. It’s a story of bioscience, advanced manufacturing, and tech—but more than that, it’s a story of implementation.

INNOVATION IOWA recently published a compelling article spotlighting the quiet but powerful transformation unfolding across our state. It’s a story of bioscience, advanced manufacturing, and tech—but more than that, it’s a story of implementation.

That’s where ADVANCE IOWA comes in, we joined UNI’s Metal Casting and Foundry 4.0 Centers in a national Foundry 4.0 Partnership to accelerate Industry 4.0 adoption in foundries and supply chains. While the formal contract has ended, the partnership has not—our daily collaboration with Foundry 4.0 (F4C) and the Metal Casting Center (MCC) continues, united by shared values and long-term strategic impact.

Today, ADVANCE IOWA remains a driving force in this innovation ecosystem. Our outreach and education efforts help manufacturers connect I4.0 concepts—like smart sensors, automation, and data analytics—to real-world value. Through tools like our Industry 4.0 assessment, we help businesses evaluate current operations, identify gaps, and uncover transformation-ready solutions.

We're also part of the Last Tactical Mile (LTM) Impact 2.0, a seminar series initiative through America Makes, that focuses on Additive Manufacturing for Metal Casting and aims to elevate education and networking for foundries and their supply chains. UNI’s Metal Casting and Foundry 4.0 Centers will host one of these seminars in spring 2026—advancing not just technologies, but innovation and progress.

This isn’t just a story about Iowa—it’s a national blueprint. When strategy, technology, and values align, innovation becomes tangible. The article doesn’t just recognize our mission—it reinforces it.

Call or email Todd E. Hutcheson and explore Industry 4.0 and how it could transform your business!

Seminar & Workshop Opportunities

We are excited to announce that we are currently planning new workshops! While we do not have specific dates yet, our partners are actively hosting a variety of workshops throughout the year focused on Industry and Foundry 4.0.

We are excited to announce that we are currently planning new workshops! While we do not have specific dates yet, our partners are actively hosting a variety of workshops throughout the year focused on Industry and Foundry 4.0.

The Last Tactical Mile (LTM) seminar sessions are all-day educational opportunities designed to equip foundries, supply chain partners, and technical professionals with the knowledge and connections they need to thrive in this evolving landscape.

Upcoming LTM | Impact 2.0 Seminar Series

Additive Manufacturing for Metal Casting

Event Details:

March 11, 2025

8:15 am (Check–in)

All–day learning event, free of charge.

Rio Hondo Golf Club & Event Center, Downey, CA

This seminar is at no charge! Defense Acquisition Professionals earn 7 Continuous Learning Points (CLPs) for attending, contact Brittany Engel at bengel@ybi.org for details.

FOUNDRY 4.0 Discover Tomorrow Today

Building Resiliency in the Casting Industry

Understanding Foundry 4.0 technologies is crucial for transformative change.

The last two years Todd E. Hutcheson, Director of ADVANCE IOWA, spoke at the AFS Castexpo & Metalcasting Congress. His first presentation in 2024 was focused on the practical implications of Foundry 4.0 for businesses titled "Why INDUSTRY 4.0? Connecting Inputs to Assessments to KPIs to Business Value."

Todd’s second and most recent presentation was titled "Building Resiliency in the Casting Industry: Using Composite, Industry-wide 4.0 Assessment Lessons Learned and Best Practices.” During this presentation, he provided answers to key questions using findings, best practices, and lessons learned from industry-wide data gathered during a two-year Foundry 4.0 Partnership in collaboration with the NCDMM and several strategic partners nationwide.

The comprehensive data, benchmarked against industry metrics, highlights the significant value and growth opportunities of strategic Foundry 4.0 implementation. Download the presentation to learn from his expertise and discover how these enhancements can drive transformative change, resulting in higher quality products, increased customer satisfaction, and a stronger market position.

A Foundry 4.0 Center Case Study

Rada reached out to the University of Northern Iowa (UNI) Foundry 4.0 Center after hearing about their expertise in foundry processes. After a brief tour at Rada with UNI staff, it was clear that Industry 4.0 initiatives were of significant interest. Rada employs equipment in their foundry that uses legacy control systems. The UNI Foundry 4.0 Center suggested the implementation of low-cost sensors to acquire process data that would describe how the seasoned veterans are creating that high quality, American craftsmanship that Rada and their customers value.

For more information on workshops and events at the UNI Foundry 4.0 and Metal Casting Centers, please visit the following link:

The UNI Center for Business Growth & Innovation

CBGI was part of a successful partnership with the Department of Defense to aimed to foster growth, cultivate innovation, and incorporate Industry 4.0 technologies and automation for the foundry industry and their supply chain. Our team provided resources, networking platforms, and the workshop and training programs to adapt challenges into profitable opportunities for sustainable futures!

Let's talk.

8120 Jennings Drive | Cedar Falls, IA 50614

319-273-4692 | info@advanceiowa.com

Todd.Hutcheson@uni.edu

Janell.Crow@uni.edu